The Cement Plant Rotary Kiln in Operation YouTube

Apr 15, 2018· Subscribe to Smiling Star for more technology and education videos.

WhatsApp)

WhatsApp)

Apr 15, 2018· Subscribe to Smiling Star for more technology and education videos.

Metallurgical ContentRAW CEMENT GRINDINGWET VS DRY Grinding of CementCLINKER GRINDINGCement Grinding MillsHigh Efficiency Cement Grinding Mill The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. Rod Mills for raw and finish grinding begin to enter the picture. Larger .

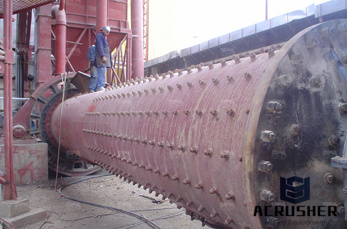

For cement production line, there are many cement equipments among which cement preheater is included. Rotary kiln is used widely in cement plant, and we design and produce newstyle rotary kiln with vertical preheater which takes use of the heat of the flue gas coming out from the kiln end to preheat the dolomite to 800℃ in the preheater.

cement plant using esp for raw mill YouTube The next video is starting stop. Loading... Ftbtoiy SgdtKiln And Raw Mill 33 Crusher Plant Requ. Largescale crushing screening milling plants. ... kiln and raw mill 33 principal of kiln in cement plant.

operation principle of vsk cement plant. clinker from rotary or vertical shaft kiln International Cement ... Plants; Data ... I know that the disadvantages of the VSK kiln are the inclusion of ash ... a well working VSK and a well working SP Rotary kiln,what could be ... There are at least 2 principle reasopns why the clinker from a VSK...

Principal refractory performance issues in the rotary kiln, refractory materials, process efficiency of linings, inspection, repair and maintenance, optimised refractory usage. A total course for cement production staff who, until now, have only been able to ''learn on the job''. Course Content. Overview of refractory materials

The cement kiln is a typical example of a sintering furnace. Kilns are used in the cement industry for calcining lime and are made in various forms. Rotary cement kilns as used in the cement industry take the form of a long cylinder supported on rollers. They vary .

CO2 Emission Reduction in the Cement Industry. Article (PDF Available) ... consumption of a kiln process in the Usje cement plant is GJ/t cli nker. It can be noted that there is still .

The Cement Kiln and Energy. A medium size rotary cement kiln has an enormous appetite for energy, consuming up to 300 million Btu/h (Figure 1). Holnam''s kiln in Clarksville, MO, is the largest in the world, with a 25ft. () diameter kiln 760 ft. (231m) long. When the plant was built in the 1960''s, the kiln was the largest piece of moving ...

Aggregate Crushing Plant. Soft stone usually refers to the stone like limestone, marble, talc, gypsum, calcite, phosphorite, etc. The classic production line for the soft stone is JAW CRUSHER (primary crusher) + IMPACT CRUSHER (secondary crusher), and with the auxiliaries of vibrating feeder, vibrating screen belt conveyors.

The raw materials are passed through here and turned into oxides to be burned in the kiln. Stage 4 Kiln Phase. The kiln phase is the principal stage of the cement production process. Here, clinker is produced from the raw mix through a series of chemical reactions between calcium and .

Cement kiln Wikipedia. Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium silicates. Over a billion tonnes of cement are made per year, and cement

5. Target Setting in Cement Plants 7 Grouping of Cement plants 7 Energy Consumption Range 8 Example: Normalised Baseline parameters and Target for PPC 8 Apportionment of SubSector Target of Energy Saving in Cement Sector 9 Apportionment of Target of Energy Saving in individual Cement plant 9 6. Normalization 10 ...

Cement manufacturing process components of a cement plant from quarry to kiln to cement mill. Read More. Cement Vertical Roller Mill Great Wall Machinery ... Types of cement mills in use today .... o Principle of separation ... Difference between good poor mill operation maintenance can results in.

There is considerable scope to use this methane as an alternative fuel in cement kilns. In fact, a Lafarge plant located just outside Kansas City (USA), is already using methane gas from two nearby landfill sites, using an underground pipeline system. The plant is thereby .

cement plant work principle educationcarein. Working principle of the concrete batching plant Concrete batching plant is divided into four parts: sand feeding, powder (cement, fly ash, bulking agent, etc) More details » Get Price Continuous surveillance of kiln shell temperature Cement Lime .

Typical plant costs range upwards of Rs. 1500 crores (USD 250 Million) a fairly substantial fixed investment. In order to pay off this huge capital cost as well as to maintain kiln integrity, the cement plant must produce continuously 3 shifts per day! In addition, the plant must comply with severe environmental constraints.

Jul 16, 2019· Holcim Cement''s Midlothian cement plant has requested a permit application to the Texas Commission on Environmental Quality to release an additional 2700 tons per year of Carbon Monoxide and burn Petroleum Coke in its Kiln # estimates these change will set of federallymandated reviews for increases in emissions of Particulate Matter (PM), Nitrogen Oxide (NOx), Sulfur .

Use of Alternative Fuels in Indian Cement Industry 349 TDF as alternative fuel. The expenses require for the different trials and tests are imposed on that individual plant. This is a costly affair and a stumbling block in use of alternative fuel in Indian cement plants. Combustion in Cement Kiln

clean and safe environment. Cement kiln dust (CKD) is a significant byproduct material of the cement manufacturing process. Over the past several years dramatic advances have been achieved in the management and use of cement kiln dust, thus reducing its dependency on landfill disposal.

Cement''s Essexville, MI grinding plant. The cement industry lost mmt of finish grinding capacity since the previous survey. Since the 2010 survey, Essroc Cement Co.''s Essexville grinding plant ceased operations and Essroc''s grindingonly facility in Nazareth, PA was combined with their clinkerproducing plant – bringing the ...

Aug 30, 2012· Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 ⁰C. This temperature begins a chemical reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide.

A rotary kiln is a pyroprocessing device used to raise materials to a high temperature ... Principle of operation. The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its longitudinal axis. ... but sometimes as fast as 5 rpm. The Kilns of most modern cement plants are running at 4 to 5 rpm.

A development of this process is the ''precalciner'' kiln. Most new cement plant is of this type. The principle is similar to that of the dry process preheater system but with the major addition of another burner, or precalciner. With the additional heat, about 85%95% of the meal is decarbonated before it enters the kiln

WhatsApp)

WhatsApp)