Melting Sand Into Glass YouTube

Jun 09, 2017· Why Snatch Blocks are AWESOME (How Pulleys Work) Smarter Every Day 228 Duration: 16:31. SmarterEveryDay Recommended for you

WhatsApp)

WhatsApp)

Jun 09, 2017· Why Snatch Blocks are AWESOME (How Pulleys Work) Smarter Every Day 228 Duration: 16:31. SmarterEveryDay Recommended for you

However, the glass industry not only supplies construction materials but also enables the manufacturing of windshields and windows for the automobile industry. Additionally, industrial sand is used in container glass for foods and beverages, and tableware.

U value represents the amount of heat transferred through glass. If a glass is said to be insulated unit then it should have lower u value. 6. Recycle Property of Glass. Any glass can be recyclable. It can also be used as raw material in construction industry. Types of Glass and their Uses. The types of glass used in construction are ...

Nov 27, 2012· Silica Sand for Glass Manufacturing. The silica sand for glass manufacturing includes window glasses, mirrors, tableware, decorative glassware, car mirrors, TV monitor screens, fibreglass etc. The silica sand which is free from contaminants, low in iron, clear in color and consistent in grain size is used in glass manufacturing industries.

The depth and degree of the translucency of the sandblasted finishing vary with the force and type of sand used. Sandblasted glass can be used in numerous interior design applications in both residential and commercial settings: doors, shower screens, partitions and interior screens, furniture, etc. Acidetched Glass

Sand (SiO 2) Manufacture of glass. ... Types of glass. There are nine types of glass according to the minor additions and variations in the ingredients used and according to the methods of manufacturing. The different types of glasses are different in their properties and uses. 1. Soda glass or sodalime glass:

Glass is made from silica sand. Silica sand consists primarily of silicon dioxide, usually tiny weathered pieces of quartz, but there are other silica minerals as well. Silica sand is the most common type of sand in deserts. Quartz is a very hard ...

Oct 27, 2012· This is a chemistry video for grade 1011 students that elaborates the process of glass making in glass industry. ... From sand to glass ... Glass Manufacturing,Properties,Use Types ...

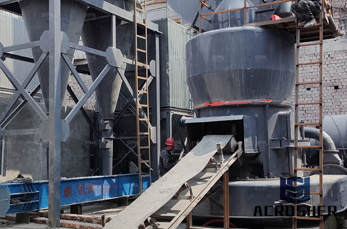

Manufacturing of Sand process involves three stages, crushing of stones in to aggregates by VSI, then fed to Rotopactor to crush aggregates into sand to required grain sizes (as fines). ... Sand made by other types of machines is flaky, which is troublesome in working. The Jaw crushers, are generally used for crushing stones in to metal ...

Glass is the oldest, and most familiar, performance fiber. Fibers have been manufactured from glass since the 1930s. Types of Glass Fiber As to the raw material glass used to make glass fibres or nonwovens of glass fibres, the following classification is known: 1. Aglass: With regard to its composition, it is close to window glass. In the ...

The glass furnace is a horizontal type, as described above. ... The natural resources in glass manufacturing are sand, limestone, and soda ash. Although these resources are abundant in the United States, they are geographically separated by long distances, which leads to high transportation costs in procuring these raw materials. ...

Manufacturing glass articles requires the ability to balance quality control and productivity. We assist glass manufacturers in their pursuit of continually improving quality, while often providing the added benefit of cost reductions. With services that include glass manufacturing audits, the costeffective evaluation of a bottle design prior to mold construction and the diagnosis of a ...

There are four main raw materials used to make glass: silica sand, soda ash, dolomite and limestone. In many cases, broken pieces of glass called cullet are also added to these raw materials to help them properly melt when heated. There are a number of different ways to make glass, depending on the desired finished product.

Jan 22, 2020· Silica sand is used throughout the world, and in so many different ways it is hard to imagine a world without it. From water filtration, to glass manufacture, to industrial casting, to sand blasting, to producing concrete, to adding texture to slick roads, silica sand impacts every aspect of .

The most common use for sand is in the manufacture of silicon computer chips. Sand has been used widely in the construction industry for many hundreds of years. Romans produced building tiles out of sand. Tile manufacturing companies have mixed sand and lime together to make a special brick to use as a building material.

SAND AND SAND MINING Part I. Source: Unknown Uses of sand This resource is sand, not sand and gravel. Its primary source is sand dunes, therefore Michigan ranks third in the US in industrial sand production. Silica sand is the major component of glass, foundry molds, and abrasives. It is also used in ceramics, on golf courses, and as a filter ...

A wide variety of glass sand options are available to you, such as silica oxide micro fine 400, silica ultra fine500. You can also choose from silica quartz, silica powder glass sand, as well as from refractory, surface coating glass sand There are 43,075 suppliers who sells glass sand on .

Some sand is from Britain and Ireland and most of the glass factories in the use this sand. There are different types of glass and each uses a slightly different mix of raw materials. The sand, limestone and other ingredients are carefully weighted and melted together in a .

There is not one specification for glass sand as a result of the many different types of glass that can be produced. Each glass has differing chemical and physical properties which require the use of different glass sands. Most of the commercial glass in everyday use is sodalimesilica glass. This includes: Bottles; Glass jars

Not all types of sand can be used because the grains may be too angular and may not flow properly through the neck of the hourglass. White quartz sand, the sand found on sparkling white beaches, is attractive but not the best for hourglassmaking because it is too angular and does not flow smoothly.

Abrasive blasting, more commonly known as sandblasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface pressurised fluid, typically compressed air, or a centrifugal wheel is used to propel the blasting material (often called the media).

here. Sodalime glass consists of sand, limestone, soda ash, and cullet (broken glass). The manufacture of such glass is in four phases: (1) preparation of raw material, (2) melting in a furnace, (3) forming and (4) finishing. Figure is a diagram for typical glass manufacturing.

Sand provides bulk, strength, and other properties to construction materials like asphalt and concrete. It is also used as a decorative material in landscaping. Specific types of sand are used in the manufacture of glass and as a moulding material for metal casting. Other sand is used as an abrasive in sandblasting and to make sandpaper.

Flat Glass Manufacture. Flat glass is used in homes, vehicles, public buildings, offices, hotels, shops etc. and the most popular method of production used is the float glass process. The Float Glass Process. This method of making flat glass is the most popular method used by manufacturers and requires a great deal of initial capital to start up.

WhatsApp)

WhatsApp)