Modeling of a medium speed coal mill

Download Citation on ResearchGate | Modeling of a medium speed coal mill | This paper presents a coal mill model that considers the effect of coal moisture on its accuracy. This mathematical model ...

WhatsApp)

WhatsApp)

Download Citation on ResearchGate | Modeling of a medium speed coal mill | This paper presents a coal mill model that considers the effect of coal moisture on its accuracy. This mathematical model ...

Pulverizer . A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in .

article{osti_, title = {Techniques and relative energy requirements for finecoal grinding}, author = {Notestein, }, abstractNote = {The Coal Grinding Task Group basically characterized coal grinding technology (June 1982) with an emphasis on identifying any needs related to producing very fine coal (<325 mesh). The underlying assumption was that future coal usage in nondesigned ...

A new modelbased approach for power plant Tubeball mill condition monitoring and fault detection. ... the complete coal mill model for the mill normal grinding process is described by,, ... from EDF Energy and Mike Garwood, Will Quick from UK for their great support and advices; the authors also thank BCURA (85A/B) and EPSRC (EP ...

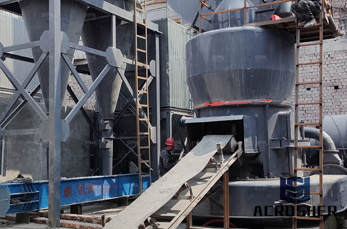

offers 17,010 coal mill products. About 26% of these are mine mill, 1% are flour mill, and 1% are other energy related products. A wide variety of coal mill options are available to you, such as raymond mill, ball mill. You can also choose from free samples, paid samples. There are 16,970 coal mill suppliers, mainly located in Asia.

Nonlinear coal mill modeling and its application to model predictive control. ... This limit is imposed by the size of the coal mill and by the available grinding capacity of the rollers. The parameter BR 1 can be used to simulate a deterioration of the roller performance ( due to .

2017 Lianke machinery 3r coal grind mill 3R500 model 3 roller vertical raymond ... rock phosphate, coal and other materials, total about 400 kinds of materials. Products Show Working Principle of Ball Grinding Mill The energysaving ball mill is a horizontal cylindrical rotating device, outer gear, the two positions, lattice energysaving ball ...

Pulverizer Wikipedia coal mill model uml diagrams,A pulverizer or grinder is a mechanical device for the grinding of many different types of example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plantsp amp i diagram for cement mill amp i diagram for cement mill coal mill model uml diagrams ...

Grinding analysis of Indian coal using response surface methodology ... Abstract The present work discusses a systematic approach to model grinding parameters of coal in a ball mill. A three level ... Grinding analysis of Indian coal using response surface methodology 185 123.

Patent CNY Fire coal power plant boiler cold ... The utility model provides a fire coal power plant boiler cold state pulverizing apparatus, comprising a coal mill, an .

Aug 13, 2019· HBM series vertical energy saving vertical grinding mill machine researched and developed by our company engineer who have been spending his whole life basing on the national mill "E"model ...

main tenance state of eac h mill. 2. CO AL MILL MODELING The MPC con troller for coal mills is based on a nonlinear ph ysical mo del to describ e the grinding, drying, and separation pro cesses o ccurring in typical coal mill pulv erizers. Similar mo dels ha ve b een describ ed b y F an and Rees [1994], Zhou et al. [2000] and Niemczyk et al ...

offers 4,651 coal grinding mill products. About 68% of these are mine mill, 4% are grinding equipment, and 1% are flour mill. A wide variety of coal grinding mill options are available to you, such as raymond mill, ball mill, and end mill.

Air swept coal mill is an ideal coal processing equipment that can both grind and dry, with characteristics of high efficiency, energy saving, environmental protection, 8% and above of its grinding coal can pass through the 200 mesh screen, and the water content can be under 2%, it is an ideal grinding equipment for coal powders that are used in industrial furnaces and rotary kilns and other ...

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process ...

2 Figure 2 Tube Ball Mill Structure II. MATHEMATICAL MODEL OF TUBEBALL MILL The procedure for coal mill modelling can be broken down into the following steps: 1) ΔTo derive the basic mill model dynamic equations through analyzing the milling process, applying physics and

offers 13,449 coal mill machine products. About 31% of these are mine mill, 2% are grinding equipment, and 1% are flour mill. A wide variety of coal mill machine options are available to you, such as raymond mill, ball mill.

It achieves the goal of high yield and high fineness and provides an efficient and energysaving grinding equipment for the production of high quality pulverized coal. Customer stories Group purchased from CHAENG coal mill used in 1000t/d cement production line. The coal mill .

Product Name Coal Grinding Mill manufacturer Model YGM7826 model Color White, Yellow, Blue, Red Standard CE ISO Capacity 25500kg/h based on different hardness materials Motor power for main unit, 15KW for blower, for the classifier Fineness can be adjustable Used building industry machinery, mining, chemical and so on Products Show Spare parts Our .

The ball mill is used for grinding materials such as coal, pigments, and feldspar for pottery. Grinding can be carried out either wet or dry but the former is performed at low speed. Blending of explosives is an example of an application for rubber balls.

The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control. The model is developed by using the mass and heat ...

During the coal grinding process, the coal is crushed and its superficial area increases continually. To add new superficial area, the bond between solid molecules must be overcome, so the energy is consumed. The coal is grinded into pulverized coal in the coal ball mill mainly by means of three ways: press, strike and grind. Among them, the ...

PDF | The use of coal in the steel industry, similarly as in the whole national economy, is often preceded by its pretreatment. Coal is mined in the form of big solids, but, being in such a form ...

A unified thermomechanical model for coal mill operation ... Dynamic coal mill model based on conservation laws and empirical relations. •. A model which can replicate the entire milling operation from startup to shutdown...

WhatsApp)

WhatsApp)