(PDF) A comparison of wear rates of ball mill grinding media

A comparison of wear rates of ball mill grinding ... A comparison of wear rates of ball mill grinding ... difference between the d ifferent grades was not as marked.

WhatsApp)

WhatsApp)

A comparison of wear rates of ball mill grinding ... A comparison of wear rates of ball mill grinding ... difference between the d ifferent grades was not as marked.

Mar 11, 2014· You can carve with just the tip to get great detail and smooth contours or they can move a lot of material just like an end mill. I used a 1/2″ ballnose bit to carve a wooden sink. For intricate 3d carving, consider a tapered ball nose bit like these. The slight angle of the cutting edge helps reduce the appearance of tool marks parallel to ...

to ball filling variation in the mill. The results obtained from this work show, the ball filling percentage variation is between – % which is lower than mill ball filling percentage, according to the designed conditions (15%). In addition, acquired load samplings result for mill ball filling was %.

May 23, 2014· What is the difference between a vertical roller mill and a ball mill? Answer. ... The inks usually have a greater range of colors. They tend to write finer lines. ... the difference between a red ...

Working Principle Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the ...

intermediate size ready for final grinding in a ball mill, pebble mill, or VERTIMILLTM. Wet grinding is accomplished in a slurry of 50 to 80 percent solids. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

For Pb, the two puck mills produced the greatest concentrations, followed by the ring and puck mill for which metals concentrations were greater than the ball mill (ConoverIman p < ). There were no statistically significant differences between the two unmilled techniques and .

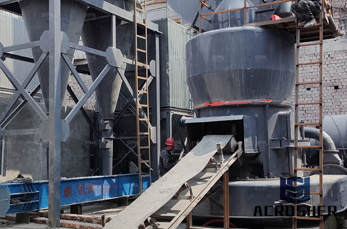

Ball mill is the material to be broken, and then smash the key equipment, widely used in cement, silicate products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metal and glass ceramics and other production industries of all kinds of ores and other grindable materials can be .

Grinding Characteristics of Coal and Petroleum Coke/Coal Blends on Utilization for Combustion. ... characteristics of PC blend with coal in a laboratory ball mill to meet an industrial tube mill ...

The rotating speed of the cylinder is below the critical speed. In order to obtain a better impact effect, some ball mill speed can be adjusted. Ball mill and rod mill are used in wet and dry processes to deal with various hardness of ore, rock and other materials. So what are the differences between ball mill and rod mill.

Bull end mills are simply corner radius end mill cutters. These radius end mills are single ended tools used for making corner radii at the bottom of a milled shoulder. Corner radius end mill cutters have a stronger milling edge than square end mills, so feed rates may be increased and yield longer tool life and greater productivity.

The Difference Between PF Impact; Kaolin Washing Plant For Sale; Difference Between Artificial Sa; Quartz Grains Making Plant; Ball Mill Manufacturer in China; Ball Mill Operation Manual; Second Hand Belt Conveyor; Cone Crusher Spare Parts Eccen; Jaw Crushers for Sale in Rock Qu; HPC220+CSB240 Gravel Crushing Pl; Mobile Jaw Crusher Operation

Apr 09, 2019· The 2 flute have a larger gullet so more chip clearance. For smaller mills (below 1/2 inch) a 2 flute is a better roughing mill. For finish work or in hard materials, you need more cutting edges so use a 4 flute. If you''re going to be working in aluminum, you''ll want to get some "high Helix" end mills. The same principle applies between 2 and 4 ...

The ball mill is easy to overgrind, the limestone unit wear is generally 46 g/ton, and the ball mill is up to 500 g/ton. 4) When grinding white minerals by vertical grinding, the effect on whiteness is much smaller than that of ball mills. 8, environmental impact 1) Vertical grinding is at work, the sound is soft, generally around 80 decibels.

Introduction to Milling Tools and their Application ... Understand the difference between cut speed and feed rate ... Ball end mills produce a radius at the bottom of pockets and slots. Ball end mills are used for contour milling, shallow slotting, contour milling and pocketing applications. ...

difference between the different grades was not as marked. It is concluded that untrained personnel can use a simple ... Ball mill balls experience a greater number of impacts, but at lower magnitude than SAG mill balls, due to the smaller ball size, and smaller mill diameter. Feeds are typically highly abrasive, contributing 10 – 15 µm/hr ...

See the difference and try one of our end mills today to see how they are better than the rest. Other Options Available. We understand that ultraperformance end mills may not be what everyone is looking for. In that case, we''ve designed an allpurpose and highperformance line of end mills so that everyone can find end mills suitable for their ...

Oct 11, 2019· At present, the most widely used grinding equipment in the dressing plant is ball mill and rod mill. As far as the working principle is concerned, both ball mill and rod millare the same. The grinding medium (steel ball or steel rod) installed in ...

Differences between a ball mill greater long. ... with great utility Operating work indices can be used to evaluate individual units in a conventional The apparent difference between ball mill and AGSAG mill efficiency is an artefact of Bonds implicit assumption that the particle size.

Minetomill optimisation: effect of feed size on mill throughput No. 48 SRK Consulting''s International Newsletter One of the most valuable aspects of blasting is the generation of very fine particles (, smaller than 12mm) that will pass through the primary mills and onto the secondary ball mill circuits, alleviating a common bottleneck.

1 CONGA: THE WORLD''S FIRST 42 FOOT DIAMETER 28 MW GEARLESS SAG MILL T. Orser1, V. Svalbonas 2 and *M. Van de Vijfeijken 3 1Newmont Mining Corporation 10101 East Dry Creek Road Englewood, CO 80112, USA 2Metso Corp. 2715 Pleasant Valley Rd.

Jun 27, 2019· The difference between the result gotten from using wet and dry milling are most of the time very large. This difference is attributed to the power. The power to drive a wet ball mill is said to be 30% lesser than that of a similar dry ball mill. Nature Of Materials

An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit in its application, geometry, and manufacture. While a drill bit can only cut in the axial direction, a milling bit can generally cut in all directions, though some cannot cut axially.

Roller mills are the most common mill used in the Corn Belt. They are more energy efficient and generally result in a more uniform particle size than hammer mills. However, hammer mills are still in use, and preferred when the feed will be pelleted or a need for greater flexibility in particle size.

WhatsApp)

WhatsApp)