(DOC) VAT LEACHING AND ELUTION PLANT GOLD .

The manual is all about VAT Leaching Technology which is a low cost technology for recovery of gold from fresh ore or from tails left from previous CIL process and from Small Scale Miners.

WhatsApp)

WhatsApp)

The manual is all about VAT Leaching Technology which is a low cost technology for recovery of gold from fresh ore or from tails left from previous CIL process and from Small Scale Miners.

Sep 16, 2007· How gold is produced, from excavation to ingotform. How gold is produced, from excavation to ingotform. ... The Process of Excavating and Refining Gold Triwood1973. Loading...

Mar 14, 2013· Jewelry manufacturing process• Jewelry manufacturing process includes most advance technologies and dedicated research. Jewelry making is a very composite process undergoing a long and slow procedure making it tough from the initial point to the concluding point. Each product undergoes a series of procedures before we get the net product as a ...

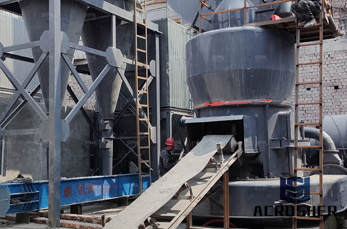

Gold Processing Plants. Star Trace offers turnkey solutions for gold processing plants. Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of gold processing plant equipment. We specialize in gold processing plants, gold trommel plants and portable gold trommel plants.

Compact disc manufacturing is the process by which commercial compact discs (CDs) are replicated in mass quantities using a master version created from a source recording. This may be either in audio form or data form ().This process is used in the mastering of readonly compact discs; CDRs, CDRWs, and DVDs are made somewhat differently, though the methods are broadly similar.

The IGR 100 Modular Gold Processing Plant is a selfcontained fine gold recovery equipment system. It uses classification and enhanced gravity to assure you are catching the finest gold and the big nuggets. In the standard configuration material flows as follows: The miner feeds sand/gravel into the vibrating screen The screen divides your feed into 2mm plus 2 mm minus size fractions The 2mm ...

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery ...

Buy used Processplants from King Industries. We can help guide you to the best solution for your equipment needs. ... USED 3,000 6,000 TPD Gold Process Plant with CIL CIP. Manufacturer: Inventory ID: 18CAL01. View Details. 20,000 TPD Heap Leach Crushing Plant .

Sep 25, 2012· New Release the RG30 is an entrylevel, low capex gold processing plant recently added to the APT Ground Breaker product line. Designed to be used in .

Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earth''s crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in diameter, and on rare occasions ...

The chart/table below are crude budgetary estimations for the cost of major plant equipment. Actual cost will vary depending of the process details and detailed equipment list and origin. Please use this to decide if your project and dream for becoming a miner or mining company is something you can afford. This is only an approximation.

JACOBI CARBONS PROCESS FOR GOLD ORE EXTRACTION AND REACTIVATION After crushing and milling the ore is introduced to mixed cyanide and other reagents. The solids are separated and the pregnant solution is repeatedly contacted with granular activated carbon to strip the gold complex from the liquor. ... manufacturing plants, reactivation plants ...

Apr 19, 2008· Can plants experience stress? ... You want to know manufacturing process of gold potassium cyanide ... Virtual manufacturing is the process of designing a product or creating a manufacturing ...

Manufacturing Plant Construction Should your company wish to construct a manufacturing plant, Ai Process is your ideal engineering partner. Ai Process are specialist process engineering consultants that design and build manufacturing plants and provide turnkey manufacturing plant construction services throughout the UK and the world. We provide all aspects of manufacturing plant .

118 Process Plant Manager Gold jobs available on Apply to Plant Manager, Supply Chain Manager, Operations Manager and more! ... Technical experience and familiarity with all facets of manufacturing processes.

CONCLUSIONS: Small Gold Processing Plant for Sale! The developed flowsheet provides a Small Gold Processing Plant which can be efficiently operated by one operator per shift or with a helper if local requirements so dictate. Power requirements are such as to be available from a portable generator and water requirements are held to a minimum.

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Moving Your Manufacturing Forward. Customers in industrial, manufacturing and processing industries such as automotive, aerospace, packaging, food and beverage, oil and natural gas and many others rely on Graco''s expertise in liquid finishing, sealants and adhesives, lubrication, sanitary, fluid transfer, chemical injection and more.

Feb 02, 2012· Amazing Modern LPG Cylinders Manufacturing Process And LPG Cylinders Filling Plant ... Gold How its made Duration ... Process video of Sugar Mill / Sugar Manufacturing Process .

Detailed Project Reports Profiles on Gold Potassium Cyanide Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue

The slurry that remains after this process has a very fine particle size. Typically, 80% of the ore particles are less than 70 microns in size (about the same consistency as fine beach sand). Such a fine particle size is required for gold liberation – the size required for the cyanide to be able to ''see'' the gold in the leaching process.

The Kent Flexible Plant is the only plant with three ongoing manufacturing processes, roasting the Starbucks and Seattle''s Best Coffee brands, blending Teavana TM/MC tea and a flexible soluble line for Starbucks VIA® Instant. Built in 1992, Kent is the oldest plant in the company and just 13 miles away from the Starbucks Support Center.

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore ...

process has been practiced, but there has been little incentive to process tailings in this way in the past. With. the development of technologies that make it possible to recover and recycle free or complexed cyanide directly from gold plant slurry tailings, which indicates, on paper at .

WhatsApp)

WhatsApp)