Leading cement equipment supplier of cement production ...

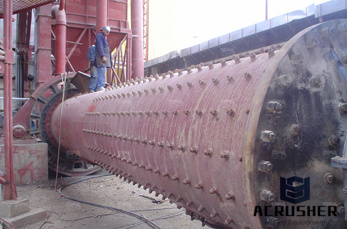

AGICO is specialized in design and supply equipments for complete cement production lines of different scales, capacity from 300 to above 2500TPD,main equipments:Rotary Kiln, .

WhatsApp)

WhatsApp)

AGICO is specialized in design and supply equipments for complete cement production lines of different scales, capacity from 300 to above 2500TPD,main equipments:Rotary Kiln, .

Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. ... Portland cement accounts for 95 percent of the hydraulic cement production in the United States. The balance of domestic cement production is primarily masonry cement. ... ball or tube mills, thereby ...

Cement clinker making plant we use in this whole production line are vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating system, cement rotary kiln and packing machine and so on. All the Cement equipments in t.....

Dec 11, 2016· The Pozzolana cement production line is the production of cement a series of cement equipment ball mill for pozzolana cement blending non metallic mineral ball mill cost for 100 ton cement ...

Vertical Roller Mill In Cement Production Line Vertical roller mill is the key equipment in the cement production line,but as we all known,the differences between raw and cement ... loesche to supply tanga cement company with two vertical roller mills 29 Jan 2014 ... Tanga Cement Company Limited, Tanzania, has awarded Loesche the order for two ...

Cambodia: Chip Mong Group has ordered three vertical roller mills from Gebr. Pfeiffer for a new cement production line in Touk Meas. The order comprises a MPS 3350 BK for coal, a MVR 5000 R4 for raw material and a MVR 6000 C6 for cement grinding. The cement mill will come equipped with a MultiDrive consisting of four drive modules.

March: Line II first cement mill starts production ACC has started investing USD in an energy program, aimed to shift its dependence on natural gas to other fuels (namely solid and refusederived fuel ("RDF")) 2014 Commissioning of coal mill ACC has now a Mmtpa cement production capacity and serves c. 8% of the Egyptian domestic ...

Optimizing cement mill using techniques at Votorantim ... Reduction in consumption of grinding media in ball mill. Cement processes are anything but simple. ... Brazil, launched a new line for cement production in 2013. After one year of operation, the company contacted ABB to optimize this new line using advanced process control techniques. ...

A decade ago, the Company decided to take the first decisive step to install a new dry clinker production line, which was put into operation in August 2014. Limestone used in the cement production is excavated in the nearby Karpėnai quarry and crushed by jaw and hammer crushers.

4 step production line of cement Our Purpose And Belief LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service, striving to maximize and optimize the interests and values of the customers, and build bright future with high quality.

Cement Production Line Cement Production Line. The grate type cooler is a kind of shock chilling cooling machine. The working principle of the cooler is the air blower blowing cold wind to cool the clinker spread on the deck board, which can make the temperature of the clinker decrease from 1200℃ to 100℃.

Cement production line is the production line composed of a series of cement production equipment, mainly involving crushing, prehomogenization, raw material preparation and homogenization, preheating and decomposition, sintering of cement clinker, cement grinding and packing and so on.

Turkey: Bolu Cimento Sanayii AS, a member of the OYAK Group, has ordered three vertical roller mills from Gebr Pfeiffer SE for the new production line at its cement grinding plant in Kazan near Ankara. Installation of the mill will expand the existing plant into an integrated cement plant. Delivery of the mills is scheduled for mid2014 and will boost the total number of Pfeiffer mills ...

cement production capacity and serves c. 8% of the Egyptian domestic cement market June: Line I first cement mill starts production June: Line II second cement mill starts production January: Clinker kiln capacity upgraded to 6,600 tpd May: Commissioning of line I (clinker) Contract signed with FL for Line I (clinker) March: Line II first

cement production capacity and serves c. 8% of the Egyptian domestic cement market June: Line I first cement mill starts production June: Line II second cement mill starts production January: Clinker kiln capacity upgraded to 6,600 tpd May: Commissioning of line I (clinker) Contract signed with FL for Line I (clinker) March: Line II first

Active lime is produced from limestone dolomite chalk and other minerals with high calcium carbonate content by the calcination process under the temperature of ° C. There are various processes for the active lime production mainly includ

Process Flow Of Stone Production Line mymeriva . 100 ton per hour stone crushing plant list and flow. ... The stone production line [1] is generally composed by several machines and it is mainly used for . ... products, which is not including the last finished stage of cement production process.

Aggregate Production Line. Capacity: 500 t/d6000 t/d Type: StoneCement Materials: Limestone Clay Gypsum etc Equipment: Cement Mill Cement Kiln etc Jiangsu Lvssn is able to supply the complete equipment and customized plan to ft the local situations. Our service covers lan d nvestigation design constructionerection commissioning and complete technical services.

Main Products: New type Ball mill/Cement ball mill/Cement production line for sale. Grid ball mill, Ball mill manufacturer Fodamon. Ball Mill The ball mill is the key material grinding equipment after it has been broken. Ball mills are widely used in cement, silicate products, new building materials.

May 08, 2015· cement production line 3d film,We provide tons per day cement plant, Vertical Roller Grinding Mill, Ball Mill, Rotary Kiln, Steel Castings, EPC Cement .

The manufacturing of cement begins with the extraction, x Grinding/drying: the raw material is ground in the raw mill to the fineness, cement production line. Contact Supplier. Gebr Pfeiffer to supply raw mill to new Itacamba cement plant. Dec 18, 2014, Gebr Pfeiffer to supply raw mill to new Itacamba cement plant, Itacamba Cemento SA has ...

Raw mills 1 and 2 were established in 1981 with Line 1. In 2014 we upgraded these from 90t/hr combined to 120t/hr as part of a CNBM China... Read More. Oman Cement Helping to build a country Global Cement ... China *10m Raw Mill Used in Cement Production Line, Find details about China Crusher Used in Cement Production Line, Tube Mill ...

Features 1. Most Advanced Production Technology The 500t/d new dry process cement production line adopts the most advanced fivestage suspension preheater, RSP/F calciner and NSP rotary large kiln hood increases the temperature of tertiary air effectively and makes the layout of .

Cement production line is the construction project to produce cement by a series of equipment. LVSSN group adopts advanced technology and equipment to improve the efficiency technical level advanced design ensure the economical investment for the cement production line.

WhatsApp)

WhatsApp)