Crushing and Screening | Mining Equipment | Pilot Crushtec

Mining Equipment for Crushing, Screening, Materials Handling, Stock Piling, Recycling, Lighting, Dust Suppression, Washing Plant. More Info: +27 11 842 5600

WhatsApp)

WhatsApp)

Mining Equipment for Crushing, Screening, Materials Handling, Stock Piling, Recycling, Lighting, Dust Suppression, Washing Plant. More Info: +27 11 842 5600

Browsing for coal washing plant for sale? The best online shopping experience is guaranteed! 3,581 coal washing plant products from 1,193 coal washing plant suppliers on for sale are available!Talk with suppliers directly to customize your desired product and ask for the lowest price, good discount, and shipping fees.

Coal Washing Plant / Coal Preparation Plant. HOT Mining is leading in the design, construction and operation of coal washing plants (coal handling and preparation plants, hereafter "CHPP").. The Joint Venture of HOT – SCCDRI has delivered over 20 CHPPs with capacity from 90 TPH to 3125 TPH.

Parnaby Cyclones designs, manufactures and installs systems and equipment for the washing, separating, dewatering and recycling for a wide range of industries and materials including: Contact us today to see how we can help you.

offers 1,912 coal washing equipment products. About 3% of these are water treatment, 1% are other food processing machinery. A wide variety of coal washing equipment options are available to you, such as metal, stainless steel.

Keeping a power plant''s boiler clean is an important part of increasing efficiency and avoiding forced outages. Power Engineering looks at different methods and practices for cleaning boilers.

Parnaby Cyclones provide a wide range of both mobile and modular coal washing plant and coal preparation equipment. Parnaby Cyclones is a long established family business. The company was founded back in 1973 by Derek Parnaby who developed the world famous ''Parnaby Process'' for minerals separation using barrels and cyclones.

Jun 01, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

The flowsheets to be simulated consist primarily of coal washing units each with a target specific gravity of separation specified for each washing unit. The feed is allocated to each washing unit on the basis of separation by size in the screening operations. This is a fairly common arrangement for modern coal washing plant flowsheets.

Techgart (Beijing) Engineering Ltd. is a leading engineering construction company offering integrated solutions to coal washing projects and material handling system.

Washing Classifying. Sand, aggregate and minerals must be washed in order to meet many required specifications for various projects. Washing and classifying equipment provides producers with the ability to remove excess water and deleterious materials such as clay, silt, shale, coal, soft stone, roots, twigs and other debris from the rock.

Coal preparation plant process and equipment for coal washing. The necessity of coal preparation Various mineral impurities are mixed in the raw coal mining process. The quality of raw coal is affected by technical equipment and geological conditions. The quality of raw coal is less and less, the meteorite mixed with raw coal is increased, the ...

how does a coal washing plant work Coal preparation plant Wikipedia, the free encyclopedia A CPP may also be called a coal handling and preparation plant (CHPP), prep plant, tipple, or wash plant .

Classification of Coal Washing Plant Over the years, the development of coal beneficiation equipment has undergone several changes in order to keep up with the excavation projects that are taking place all over the world. Naturally, the repair and manufacturing of coal beneficiation equipment .

Coal Washeries, heavy Media Separation Plants VMix will provide and supply equipment and plants for coal industry. We do supply coal wsries, Dense Media Seperator plants, Crbon/ ash recovery plants. Our flotation cells working sucessfully with high yeild, high carbon, low volatiles, low ash and low moisture content

MSI has a Large selection of Gold Mining Equipment or Gold Recovery Equipment with Gold Machine like Gold Trommel, Gold Wash Plant, Sluice Box, Gold Shaking Table, Portable Gold Trommel, Portable Gold Wash Plant, Gold Concentrator, Gold Dredge, Gold Jig, Duplex Jig, Grizzly Feeder, Conveyor, Gold Enhancer our well known Monster Red and Big Red ...

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

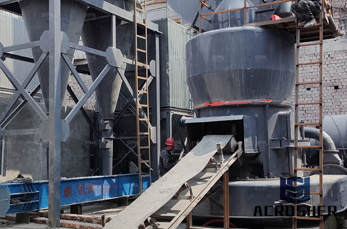

Coal Processing Coal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stations. Products: Modular Coal Preparation Plant (MCPP) comprising of vibratory screening equipment, fine coal slurry separator, magnetic separator, cyclone, heavy medium vessel, etc.

Equipment needed for coal wash processing. The equipment and process of the coal washing plant are related. The three most basic processes of the coal wash plant are the preparation work before the sorting (crushing, screening, grading), the sorting operation, and the processing of the selected products.

Coal washing is a process that is undertaken in a coal washery or coal preparation plant (CPP) where coal is refined or cleaned of impurities. Coal washing involves using water, mechanical techniques and relies on gravity and the difference of density between coal and it''s impurities which are usually more densely packed due to the fact that ...

The scheme used in physical coal cleaning processes varies among coal cleaning plants but can generally be divided into four basic phases: initial preparation, fine coal processing, coarse coal processing, and final preparation. A process flow diagram for a typical coal cleaning plant is presented in Figure

coal washing plant manufacturer/supplier, China coal washing plant manufacturer factory list, find qualified Chinese coal washing plant manufacturers, suppliers, factories, exporters wholesalers quickly on

Fine Coal Recovery and Mine Backfill Preparation: The coal mines in the Sunnyside, Ut, area have been mined continuously since 1896 and prospered as Bee Hive oven coke producers until 1924. The introduction of natural gas for firing reverberatory copper furnaces curtailed the market for Bee Hive oven coke and the mine production fell drastically.

Savona Equipment sells high quality wash plants for aggregate operations. We have several washing plants available to fit your needs. Our inventory includes wash plants for recycling water, complete with, feeder screens, sand screw, classifier, clarifier, etc.

WhatsApp)

WhatsApp)