Ball Nose End Mills • KDMB

KDMB • Ball Nose Finisher • Necked End Mills • Steel Shank. KDMB • Ball Nose Finisher • End Mills. KDMB • Ball Nose Finisher • Necked End Mills • Carbide

WhatsApp)

WhatsApp)

KDMB • Ball Nose Finisher • Necked End Mills • Steel Shank. KDMB • Ball Nose Finisher • End Mills. KDMB • Ball Nose Finisher • Necked End Mills • Carbide

Oct 19, 2006· What it is the optimun speed for a ball mill ? posted in Pyrotechnics: I have done a ball mill, recenly finished, but the motor has too rpms, is too fast for use in a ball mill (the pvc cylinder that i use, left of the shafts). With the motor i will use a 40 mm pulley, because i have a 50 mm driven pulley, in one of my two shafts. In the other side of my shafts there are two 40 mm ...

Metric Tooling. Harvey Tool''s metric offering showcases hundreds of metric tooling options, including CBN Miniature End Mills, Variable Helix End Mills, MultiFlute High Helix Finishers, and High Performance miniature metric sizes are stocked in sizes down to and are manufactured with tight tolerances for ultraprecision micromachining.

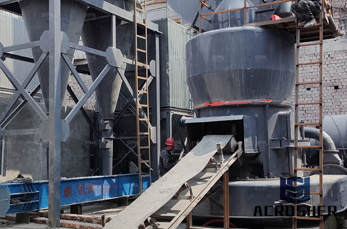

Ball Mill. Ball mill machine is widely applied in the industries, such as cement, silicate product, refractory, fertilizer, mineral processing of ferrous and nonferrous metal and glass ceramic, etc. It is mainly used to make dry or wet powder grinding of various ores and other grindable materials. Working Principle Of Ball Mill:

Lloyds''s book is the most complete and practical resource I know for information on ball milling theory and for plans to actually build your own ball mill. Here''s a shot of a nice, doublebarrel mill I built based on his principles. Homemade DoubleBarrel Ball Mill Ball milling replaces potentially unsafe hand grinding of chemicals and ...

Ball Mill dai 3600 mm Optimising Western Australia Magnetite Circuit Design IsaMill 9 Aug 2011 By using three stages of grinding, the ball mill can best be employed With a feed tonnage of 3600 tph and a final grind P80 of 34 µm the amount of grinding required for . magnetics will increase from 420 µm to 770 µm when a 3 mm screen is used at Typical magnetite ore will have ...

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

Dec 02, 2013· Over 300 different Harvey Tool Ball Miniature End Mill sizes available from .002" to .250" for your smallest machining applications. In Stock! Same Day Shipping!

For help in selecting the right milling media for you, please read applications of milling media, grinding media and balls. Milling media and grinding media are most popular in grinding processes that involve ball milling equipment such as planetary milling jars and planetary mill machines. Milling balls made of steel and ceramic are our most ...

Optimum choice of the makeup ball sizes for maximum . gives the optimum composition of 40% mm ball and 60% mm balls for a 1 m diameter mill, and 27% mm and 73% mm for a 2 m diameter mill when grinding from a 90% passing mm feed to an 80% passing 150 μm product.

Jun 20, 2015· Besides dissipating a significant fraction of the total energy consumed by the mill (for example, the outer row of 50 mm diameter balls in a 4 meter diameter mill consumes close to one tenth of ...

Nov 16, 2011· The mixer mill MM 200 is a compact versatile benchtop unit, which has been developed specially for dry grinding of small amounts of sample. It can mix and homogenize powders in .

The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing. A ball end mill is constructed of a round cutting .

Choose from our selection of ballnose end mills, including carbide ball end mills, highspeed steel ball end mills, and more. In stock and ready to ship.

Laboratory ball mill 300 mm daiaX350 mm Long also available in different sizes..... Grinding Crusher Equipment . We are instrumental in offering high quality range of Grinding Crusher Equipment which includes Hammer Crusher Mills, Jaw Crusher, Industrial Pulverizer, etc.

Jun 25, 2018· Mill effective diameter = m . 335 is a constant used for dry grinding with steel balls in the mill. Actual size of media is taken is lower than the calculated value. It is around 80 to 90 mm. If you Wants to reduce the maximum ball size, thenreduce the feed size by using pregrinding operation.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and ...

Our generalpurpose ball end mills can be used with roughing and finishing work. Discover different flutes, cutting types and other characteristics to match your project most suitably. Our end mills have compatibilities with various metals, including nonferrous, alloys and more. Create the right kind of mark of with our ball end mills.

The Figure shows that more of the material is obtained for the three ball mixture. It was also observed that a binary mixture resulted in more material reporting to the required product fineness compared to having two mills in series with one having 20 mm and other 10 mm ball size.

Retsch Mixer Mill MM 400, 100240 V, 50/60 Hz The mixer mill MM 400 is a compact versatile benchtop unit, which has been developed specially for dry, wet and cryogenic grinding of small amounts of sample. It can mix and homogenize powders and suspensions in only a few seconds.

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Optimising Western Australia Magnetite Circuit Design IsaMill 9 Aug 2011 ... By using three stages of grinding, the ball mill can best be employed ... With a feed tonnage of 3600 tph and a final grind P80 of 34 µm the amount of grinding required for .... magnetics will increase from 420 µm to 770 µm when a 3 mm screen is used at ... Typical magnetite ore will have an Ai of or less.

2 MODELLING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP Ballmill scale up (Bond''s Law)Data: zBond work index w i zFeed D f and product d size (both 80% cumulative passing) Result: The specific grinding energy w Mill power draw P = wT, where T the mill capacity Mill dimensions (from Tables or charts)

WhatsApp)

WhatsApp)