aluminum foil mill, aluminum foil mill Suppliers and ...

aluminum foil mill, Wholesale Various High Quality aluminum foil mill Products from Global Sodium Tripolyphosphate Suppliers and aluminum foil mill Factory,Importer,Exporter at

WhatsApp)

WhatsApp)

aluminum foil mill, Wholesale Various High Quality aluminum foil mill Products from Global Sodium Tripolyphosphate Suppliers and aluminum foil mill Factory,Importer,Exporter at

divided in to cold heavy rolling mill and cold finishing rolling mill. The stand type of it is four – high cold rolling mill. COLD ROLLING ALUMINUM: Novelis operates a variety of types and sizes of cold roll mills at locations around the world, including some that run at exit speeds as high as 3,000 meters per minute. STAGES IN COLD ROLLING:

New and used Aluminum Machinery and Equipment Know More. A wide variety of new and used aluminum rolling mills and other equipment including aluminum foil rolling mill, cold rolling mill, continuous casting mill and hot rolling mill, degassing box, grinding machine,multi plate filter for rolling mill oil cleaning, work rollers, plate leveling machine, extrusion plant,high precision cutting saw ...

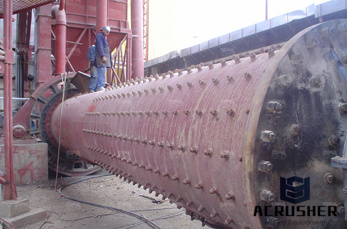

equipment used for aluminium rolling mill. Rolling Mill Equipments are widely used in steel rolling mill machinery and rolling mill plants for rolling down sheets, slabs and coils that are made up of various metals mainly aluminum, copper and stainless steel These are extensive used for production of rods, TMT, squares, angles, wires, coils, HI Beams and channels.

A wide variety of used rolling mill for aluminum options are available to you, such as kitchen use. You can also choose from bending, cutting, and punching used rolling mill for aluminum, as well as from 1000 series, 3000 series used rolling mill for aluminum, and whether used rolling mill for aluminum is t3t8, or oh112.

1700 mm Achenbach Aluminum Foil Finishing Rolling Mill: FM108. Manufacturer: Achenbach Manufacture: Achenbach Model: 4Hi 850/280 New 1990 Revamping 1997: New AFC + AGC Control Revamping 1999: Back up rolls polished device installed .

aluminum foil mill — efficient production of highquality, lowcost foil Primetals Technologies designs the most advanced foil rolling mills in the world, combining the latest developments in automated foil feed, measurement and control to enable producers to achieve the best quality foil at the lowest cost.

Aug 19, 2019· Also, on the list is the 255 million expansion of the JW Aluminum mill in Mt. Holly, South Carolina, and the investments by Arconic in Texarkana, Texas, (which was then sold to Ta Chen International Inc.) and in Knoxville, Tennessee. Each of these investments is set to address the shortfall of foil and common alloy sheet capacity in the ...

CONCEPTS Achenbach foil rolling mills are fourhigh rolling mills designed for two different applications:. Universal foil rolling mills for all strip thicknesses from mm to mm for a wide range of rolled products; Specialised foil rolling mills for foil rolling lines for graduated strip thicknesses.; Specialised foil rolling mills come in three types:

AMAG aluminum impresses with its impermeability to light, gases and moisture in the use of flexible laminates for technical applications as well as for the packaging of food and beverages. Thanks to its many positive properties in the packaging sector, aluminum foil saves more resources during its service life than are needed for its production.

An aluminium foil rolling method comprising the steps of taking two strips of aluminium, bringing facing surfaces of the two strips into contact with one another and subjecting the two strips to a first pack rolling operation, thence subjecting the same two strips to a second pack rolling operation whilst maintaining the two strips in substantially the same registry as when the first pack ...

325 aluminum rolling mill products are offered for sale by suppliers on, of which aluminum coils accounts for 13%, aluminum foil accounts for 8%, and rolling mill accounts for 3%. A wide variety of aluminum rolling mill options are available to you, such as cold rolling mill, hot rolling mill.

Aluminum Foil Rolling Mills Market Research Report covers the present scenario (Covid19 Pandemic) and the growth prospects of Aluminum Foil Rolling Mills Market for . The report covers the market landscape and its growth prospects over the coming years and discussion of the Leading Companies effective in this market.

The most advanced Aluminum Foil Mill Primetals Technologies. ALUMINUM FOIL MILL — EFFICIENT PRODUCTION OF HIGHQUALITY, LOWCOST FOIL Primetals Technologies designs the most advanced foil rolling mills in the world, combining the latest developments in automated foil feed, measurement and control to enable producers to achieve the best quality foil .

A wide variety of new and used aluminum rolling mills and other equipment including aluminum foil rolling mill, cold rolling mill, continuous casting mill and hot rolling mill, degassing box, grinding machine,multi plate filter for rolling mill oil cleaning, work rollers, plate leveling machine, extrusion plant,high precision cutting saw and others are available with .

Aluminium foil is produced by rolling sheet ingots cast from molten billet aluminium, then rerolling on sheet and foil rolling mills to the desired thickness, or by continuously casting and cold maintain a constant thickness in aluminium foil production, beta radiation is passed through the foil to a sensor on the other side. If the intensity becomes too high, then the rollers ...

Qty. 1 Secondhand foil rolling mill Mfc.: LoewyRobertson Type: 4Hi Built: Modernised: 2007 Backup roll dia.: 609 mm Roll width: 1575 mm Work roll dia.: 228 mm Rolling speed: 0300 / 600 m/min. Aluminium foil specifications: Foil Width: mm Entry thickness: mm Exit thickness: mm Coil density: 5:1 Coil OD: 1700 mm ID: 305, 415, 565 mm Weight: 7000 kg Rolling load Type ...

Aluminum rolling mills Hot strip, cold strip, thin strip and foil rolling mills are used to roll strips of light metals such as aluminum, magnesium and their alloys down to final thicknesses of mm. Copper brass rolling mills

Modern rolling practice can be attributed to the pioneering efforts of Henry Cort of Funtley Iron Mills, near Fareham, England. In 1783, a patent was issued to Henry Cort for his use of grooved rolls for rolling iron bars. With this new design, mills were able to produce 15 times more output per day than with a hammer. Although Cort was not the first to use grooved rolls, he was the first to ...

Aluminum rolling is an industry that requires process optimization and highquality enduse products. ExxonMobil Chemical has developed a tailored diluents portfolio to meet the high purity required by aluminum foils and sheet products.

Being a specialised product it is used as roll coolant and lubrication for Aluminium during reduction (Rolling) operation. It is normally componded with antioxidant and also with fats and alcohol at users end for attaining load bearing characteristics. Its application is in Aluminium Rolling Mills. ROLEX 55 is mainly used in foil to foil ...

1350mm Aluminum Foil Cold Rolling Mill. 1350mm Used Aluminum Foil Cold Rolling Mill. (Material:Aluminum) The written date is December 10,2019.

In the industrialised world, approximately 50% of all aluminium alloys used is in the form of flat rolled products. Over the last 35 years major changes have taken place in aluminium rolling lubrication development and understanding. It is now accepted that the rolling lubricant strongly influences both mill productivity and metal quality.

Single Stand Double Coiling Aluminum Hot Rolling Mill. Rough rolling is carried out on a reversible rolling mill with a thickness of 1825 mm. After doublecoiling reversible finishing rolling, the minimum rolling thickness is mm, and the .

WhatsApp)

WhatsApp)